Thay đổi ngôn ngữ :

Phân loại cáp chainflex®

-

Để giúp khách hàng dễ dàng lựa chọn cáp phù hợp, igus® đã phân loại toàn bộ các dòng cáp chainflex® theo các tiêu chí: mức tải cơ học, chiều dài hành trình, khả năng kháng dầu và khả năng chịu xoắn. Chỉ số càng cao thì khả năng đáp ứng yêu cầu kỹ thuật càng tốt.

Ví dụ: Khách hàng đang tìm loại cáp phù hợp với mức tải cơ học cao nhất, có thể di chuyển lên tới 100m cho ứng dụng chạy song song và trượt. Đồng thời, cáp cần đáp ứng tiêu chuẩn kháng dầu DIN EN 50363-10-2 nhưng không cần thiết kế chuyên biệt cho ứng dụng xoắn.

Dựa theo bảng phân loại, lựa chọn phù hợp sẽ là:

Tải: 6 Hành trình: 5 Kháng dầu: 3 Xoắn: 1

Từ đó, khách hàng sẽ tìm được loại cáp thuộc "Class 6.5.3.1", thông tin này cũng được hiển thị trong từng trang sản phẩm tương ứng.

-

| Tải | Hành trình | Bền dầu | Xoắn |

|---|---|---|---|

| từ 1 đến 7 | 1 đến 6 | 1 đến 4 | 1 đến 4 |

-

| Tải | thấp | 1 | 2 | 3 | 4 | 5 | 6 | 7 | cao nhất |

| Hành trình | không có giá đỡ | 1 | 2 | 3 | 4 | 5 | 6 | 400m + | |

| Bền dầu | không có | 1 | 2 | 3 | 4 | cao nhất | |||

| Xoắn | không có | 1 | 2 | 3 | 4 | ±360°/phút |

chainflex® có 4 phân loại tiêu chuẩn:

-

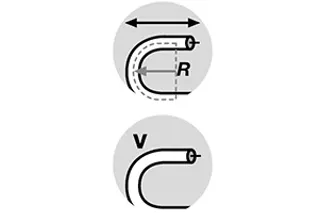

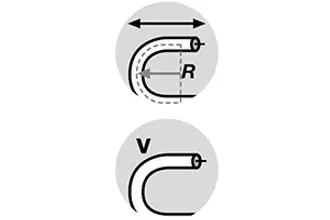

Ứng suất (R và V)

1 đến 7

- 1: Flexible cables

- 2: Cáp có độ linh hoạt cao

- 3: Cáp tương thích với xích không có cấu trúc đặc biệt (ví dụ: lõi quấn thành nhiều lớp) để sử dụng trong xích e-chain® .

- 4: Cáp có cấu trúc đặc biệt để chuyển động liên tục trong e-chains® , ứng suất trung bình, bán kính từ 7,5 xd, tốc độ lên đến 3m/giây

- 5: Cáp chuyển động liên tục trong e-chains® , ứng suất cao, bán kính từ 6,8 xd, tốc độ lên đến 10m/s

- 6: Cáp chuyển động liên tục trong e-chains® , ứng suất tối đa, bán kính từ 5 xd, tốc độ lên đến 10m/s

- 7: Cáp chuyển động liên tục trong e-chains® , ứng suất tối đa với bán kính nhỏ nhất, ứng dụng trong nhà và ngoài trời, bán kính từ 4 xd, tốc độ lên đến 10m/s trở lên

-

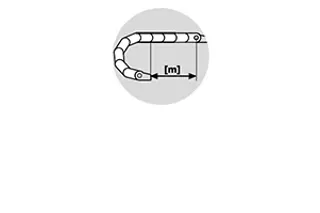

Hành trình

1 đến 6

- 1: không giá đỡ

- 2: Hành trình lên đến 10m

- 3: Hành trình lên đến 20m

- 4: Hành trình lên đến 50m

- 5: Hành trình lên đến 100m

- 6: Hành trình lên đến 400m và hơn thế nữa

-

Khả năng kháng dầu

1 đến 4

- 1: Không có khả năng kháng dầu

- 2: Kháng dầu (theo tiêu chuẩn DIN EN 50363-4-1)

- 3: Kháng dầu (theo DIN EN 50363-10-2)

- 4: Kháng dầu (theo DIN EN 60811-2-1, Kháng dầu hữu cơ (đã được thử nghiệm theo VDMA 24568 với Plantocut 8 S-MB của DEA)

-

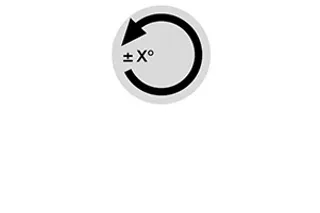

Xoắn

1 đến 4

- 1: không có xoắn

- 2: ± 90°, với chiều dài cáp 1m

- 3: ± 180°, với chiều dài cáp 1m

- 4: ± 360°, với chiều dài cáp 1m

Về mặt lý thuyết, các lớp sau đây có thể có: lớp thấp nhất "Class 1.1.1.1", highest "Class 7.6.4.3"

-

-

**Ứng suất (R và V)**1 đến 7

1: Flexible cable

2: Cáp có độ linh hoạt cao

3: Cáp tương thích với xích không có cấu trúc đặc biệt (ví dụ: lõi quấn thành nhiều lớp) để sử dụng trong xích e-chain® .

4: Cáp có cấu trúc đặc biệt để chuyển động liên tục trong xích e-chains®, ứng suất trung bình, bán kính từ 7,5 x d, tốc độ lên đến 3m/giây

5: Cáp để chuyển động liên tục trong xích e-chains® , ứng suất cao, bán kính từ 6,8 x d, tốc độ lên đến 10m/giây

6: Cáp để chuyển động liên tục trong xích e-chains® , ứng suất tối đa, bán kính từ 5 x d, tốc độ lên đến 10m/giây

7: Cáp để chuyển động liên tục trong xích e-chains®, ứng suất tối đa với bán kính nhỏ nhất, ứng dụng trong nhà và ngoài trời, bán kính từ 4 x d, tốc độ lên đến 10m/giây trở lên

-

-

Hành trình****1 đến 6

1: không giá đỡ

2: Hành trình tối đa 10m

3: Hành trình tối đa 20m

4: Hành trình tối đa 50m

5: Hành trình tối đa 100m

6: Hành trình tối đa 400m trở lên

-

-

Khả năng kháng dầu****1 đến 4

1: Không có khả năng chống dầu

2: Kháng dầu (theo DIN EN 50363-4-1)

3: Kháng dầu (theo DIN EN 50363-10-2)

4: Kháng dầu (theo DIN EN 60811-2-1, chống dầu hữu cơ (đã thử nghiệm theo VDMA 24568 với Plantocut 8 S-MB b DEA)

-

-

Độ xoắn****1 đến 4

1: không xoắn

2: ± 90°, với chiều dài cáp 1m

3: ± 180°, với chiều dài cáp 1m

4: ± 360°, với chiều dài cáp 1m

Về mặt lý thuyết, các lớp sau đây có thể có: lớp thấp nhất "Class 1.1.1.1", highest "Class 7.6.4.3"

"Class"(ification) của chainflex® là gì?

Với cáp chainflex® , igus® hiện đã cung cấp cáp cho tần suất sử dụng liên tục trong xích dẫn cáp e-chains® trong hơn 25 năm, chỉ với một mục đích duy nhất:

Vận hành an toàn.

Trong tất cả các ứng dụng e-chain® , cáp chainflex® phải đáp ứng các yêu cầu khắt khe, chẳng hạn như bán kính uốn cong rất nhỏ, số chu kỳ cao, không gian lắp đặt nhỏ và nhiều tác động hóa học và thông số động.

igus® thực hiện các tiêu chuẩn cơ bản về cáp theo tiêu chuẩn igus® tại trung tâm kỹ thuật và phòng thử nghiệm của riêng mình. Các tiêu chuẩn tiêu chuẩn chainflex® này bao gồm các chương trình thử nghiệm cuối cùng dẫn đến "Class" igus® .

Tư vấn & hỗ trợ

Hân hạnh được trả lời câu hỏi của quý khách

Báo giá và tư vấn trực tuyến

Thời gian làm việc:

Thứ Hai đến Thứ Sáu từ 8:30 đến 17:30

Online:

Thứ Hai đến Thứ Sáu từ 8:30 sáng đến 17:30