Thay đổi ngôn ngữ :

Các lĩnh vực ứng dụng cho công nghệ trục vít dẫn dryspin ®

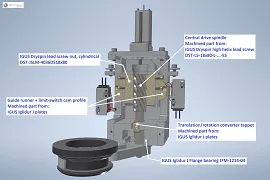

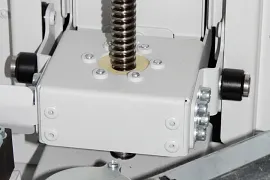

Bộ truyền động trục vít là bộ phận máy chuyển đổi chuyển động quay thành chuyển động tịnh tiến. Bộ truyền động trục vít dryspin ® luôn dựa trên các đai ốc nhựa tự bôi trơn và do đó cho phép hoạt động lâu dài mà không cần bôi trơn bên ngoài.

Công nghệ trục vít me dryspin ® dựa trên nguyên lý công nghệ tuyến tính không cần bôi trơn. Các thông số kỹ thuật và hình dạng của trục vít me, được kết hợp với đai ốc nhựa và trục ren, cùng công nghệ dryspin ® độc đáo đảm bảo tuổi thọ và hiệu quả sử dụng cao hơn nữa.

Các lĩnh vực khác nhau trong cái nhìn tổng quan

Một cái nhìn tổng quan:

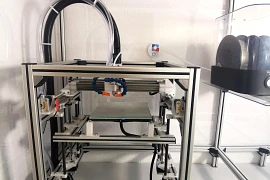

Máy in 3D/in 3D

-

Máy in 3D phòng sạch

Máy in 3D phòng sạch chính xác và đáng tin cậy để xử lý nhựa nhiệt dẻo.

-

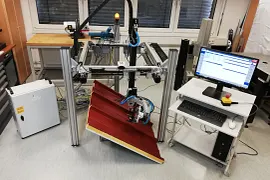

Máy in 3D cho xưởng & văn phòng

Máy in 3D khổ lớn và chính xác, phù hợp để sử dụng trong văn phòng hoặc xưởng.

-

Máy in 3D Lumifold

Máy in 3D nhỏ gọn và di động nhưng vẫn có thể tạo ra các chi tiết 3D chi tiết.

-

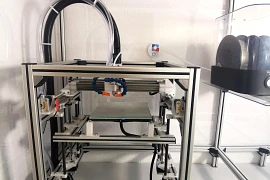

Reprap xBot

Máy in 3D có thể tự sản xuất các bộ phận thiết yếu một cách nhanh chóng và chính xác.

-

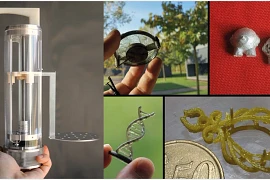

Đai ốc vít me in 3D

Đai ốc vít me thay thế cho đai ốc vít bi thông thường - trực tiếp từ máy in 3D của chúng tôi.

-

Máy in 3D thu nhỏ

Máy in 3D này chỉ cao mười cm nhưng in ra các vật thể có chất lượng cao nhất.

-

Máy in 3D Fabforge

Máy in 3D chính xác và yên tĩnh đáp ứng các yêu cầu "Sản xuất tại Ấn Độ"

-

Máy in 3D cho các thành phần công nghiệp

Các nhà thiết kế sử dụng các mô-đun tuyến tính của dòng drylin ® SAW-1040 và ổ trục trơn polymer của dòng iglidur ® J cho cơ chế điều chỉnh của bàn xây dựng.

Sàn công tác

-

Nền tảng an toàn

Một giải pháp đảm bảo an toàn hơn ở trên cao bằng cách sử dụng nền tảng an toàn SRM dạng mô-đun cho kho hàng cao tầng Euro pallet.

Máy bán hàng tự động

-

Máy đóng cốc

Máy đóng cốc tự động đóng nắp vào cốc nhựa trong các nhà hàng thức ăn nhanh.

-

Trạm laser

Một trạm laser để đánh dấu các sản phẩm công nghiệp.

-

Robot tiêm vắc-xin cho cá

Một robot delta có khả năng bắt cá và cung cấp vắc-xin cho chúng.

-

Tủ đựng bưu kiện

Một hệ thống tủ đựng tại các trạm bưu kiện giúp người dùng dễ dàng bảo trì tối đa.

-

Máy ép bánh quy

Máy ép bánh quy có khả năng sản xuất ra nhiều hình dạng khác nhau theo yêu cầu của khách hàng và thị trường.

-

Máy quét

Một máy quét di động có thể kiểm tra ngay cả các tấm phức tạp và dạng tự do bằng siêu âm trên không.

-

Máy bán hàng tự động khử trùng

Một máy rửa tự động khử trùng cốc tái sử dụng trong vòng vài giây bằng hơi nước nóng 140°C.

-

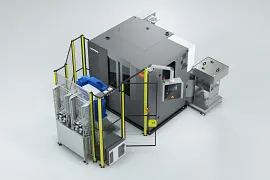

Hệ thống rửa băng chuyền

Trong ngành công nghiệp ô tô, các bộ phận phức tạp được rửa tự động sau khi sơn: Nhiệm vụ này được thực hiện bởi hệ thống rửa băng chuyền.

-

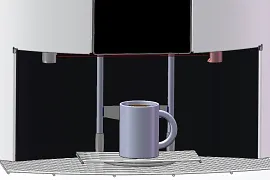

Điều chỉnh bàn tách

Các thành phần cho cơ chế điều chỉnh bàn tách tự động trên máy pha cà phê hoàn toàn tự động.

-

Máy quét sách

Trong máy quét sách để số hóa tài sản văn hóa, người ta sử dụng đai ốc ren hình thang drylin ® không cần bôi trơn.

Tự động hóa

-

Máy quấn

Tính chất trượt được cải thiện nhờ các bộ phận thay thế được in 3D trong máy quấn.

-

Máy định lượng

Một máy định lượng có nắp tự động đảm bảo đóng tự động đầu định lượng hiệu quả sau mỗi quá trình định lượng.

-

Giải pháp tự động hóa Gunda

Giải pháp tự động hóa nhỏ gọn, chất lượng cao, dễ vận hành.

Ô tô

-

Hệ thống rửa băng chuyền

Trong ngành công nghiệp ô tô, các bộ phận phức tạp được rửa tự động sau khi sơn: Nhiệm vụ này được thực hiện bởi hệ thống rửa băng chuyền.

-

Bộ nâng TV trong xe caravan

Bộ nâng TV bằng động cơ bền bỉ, chống rung và không cần bảo trì dành cho bên trong xe caravan.

-

Xe năng lượng mặt trời

Một chiếc ô tô chạy bằng năng lượng mặt trời với cánh gió bằng carbon có thể thu vào để tăng thêm lực đẩy.

Đến trang ứng dụng

-

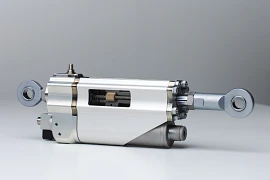

Bộ giảm chấn khung gầm

Một chiếc xe đua tự động dành cho cuộc thi của trường đại học Formula Student với một tính năng đặc biệt: bộ giảm chấn chủ động cho khung xe

Đến trang ứng dụng

-

Hệ thống phanh cho xe đua

Hệ thống phanh được hỗ trợ bởi một động cơ điện chuyển đổi chuyển động tròn thành chuyển động thẳng, do đó tạo ra áp suất thủy lực trong ống dẫn phanh

Đến trang ứng dụngCông nghiệp đường sắt

-

Cầu nối khe hở

Không có hiện tượng kẹt hoặc chuyển động mạnh của các bước trượt trong quá trình vận hành liên tục.

Máy móc xây dựng

-

Máy thoát nước tại đồng ruộng

Một loại máy cải tiến dùng để thoát nước tại đồng ruộng, có thể di chuyển các tấm thoát nước bằng nhựa trên công trường xây dựng và có thể được trải ra bên cạnh máy.

Thuyền và đóng tàu

-

Thuyền buồm đua

Một chiếc thuyền buồm đua có thể nổi trên mặt nước nhờ thiết kế cánh đặc biệt và khả năng chuyển đổi áp suất nước.

Dự án tự làm

-

Tự nâng bia

Lên xuống dễ dàng với tải trọng phù hợp, chi phí nhân công thấp, chất bôi trơn và không cần bảo trì, chống chịu thời tiết

-

Bàn bi-a

Một hệ thống truyền động có thể di chuyển một chiếc bàn cố định và có thể điều chỉnh trong hồ bơi mà không gặp bất kỳ vấn đề gì - bất chấp môi trường nước hồ bơi liên tục.

Chuyến đi

-

Giá đỡ an toàn

HAWE Micro Fluid GmbH từ Barbing ở Bavaria giới thiệu một thành phần thiết yếu dưới dạng hệ thống khóa thủy lực LE-X.

Ngành đồ uống

-

Máy rót bia

Máy rót bia tự động cho các lễ hội và sự kiện lớn để rót bia trong vài giây.

-

Máy dán nhãn

Các loại polymer hiệu suất cao chạy khô từ igus ® cho phép sử dụng nhiều cài đặt khác nhau trong máy dán nhãn của Krones.

-

Hệ thống chiết rót đồ uống

Küppersbusch GmbH sản xuất các hệ thống chiết rót đồ uống tùy chỉnh với công nghệ ổ trục igus ® .

Công nghiệp chế biến gỗ

-

Hộp gỗ dán

Công ty Silmec của Ý đã phát triển một loại máy sản xuất thùng gỗ dán

Công nghệ máy ảnh

-

Điều chỉnh góc thiết lập

Do không có chất bôi trơn và khả năng điều chỉnh vô hạn nên đai ốc vít dẫn hình thang dryspin ® đã được chọn cho ứng dụng này.

Ngành thực phẩm

-

Máy pha cà phê espresso

Một máy pha cà phê espresso có thể vận hành bằng tay và không cần điện.

-

Máy ép bánh quy

Máy ép bánh quy có khả năng sản xuất ra nhiều hình dạng khác nhau theo yêu cầu của khách hàng và thị trường.

-

Hệ thống nướng bánh wafer

Hệ thống tuyến tính trục chính chắc chắn để loại bỏ nón giấy.

Hàng không và vũ trụ

-

Mô-đun tên lửa

Một mô-đun tên lửa thu thập các mảnh vỡ không gian từ quỹ đạo Trái Đất.

-

Bướm ga máy bay

Bản sao của cánh bướm ga cho máy bay mô phỏng 737 NG và 737MAX.

-

Máy bay mô phỏng

Một cần điều khiển cung cấp hệ thống điều khiển chính xác và nhạy bén trong máy bay mô phỏng.

Đến trang ứng dụngCông nghệ y khoa

-

Tay giả sinh học

Hệ thống điều khiển của tay giả sinh học dựa trên tín hiệu EMG đến từ cơ của bệnh nhân

-

Chu vi

Chu vi, một thiết bị đo trường thị giác và xác định độ nhạy của hệ thống thị giác.

-

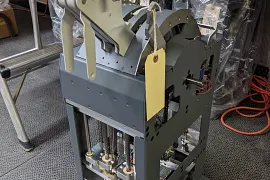

Trung tâm vỉ thuốc

Một giải pháp biên soạn và đóng gói vỉ thuốc các tổ hợp riêng lẻ lên đến 700 loại thuốc cho bệnh nhân.

-

Máy in 3D phòng sạch

Máy in 3D phòng sạch chính xác và đáng tin cậy để xử lý nhựa nhiệt dẻo.

-

Hệ thống chiết rót trong công nghệ phòng thí nghiệm

Chiết rót sạch, không cần phải vô trùng nhưng phải có độ tinh khiết cao, trọng lượng tổng thể của hệ thống thấp.

-

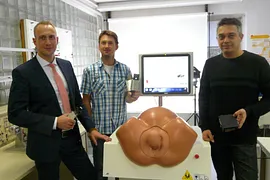

Thiết bị mô phỏng sinh nở

Quá trình sinh nở được mô phỏng tối ưu với sự trợ giúp của thiết bị mô phỏng sinh nở SIMone từ 3B Scientific GmbH.

-

Thiết bị thí nghiệm để xử lý chất lỏng

Ứng dụng cực kỳ sạch sẽ của sản phẩm igus ® , cũng như hiệu suất cao và tốc độ nạp liệu nhanh.

Sản xuất đồ nội thất / Thiết kế công nghiệp

-

Buồng thử nghiệm

Một buồng thử nghiệm có thể chuyển đổi thành bàn họp chỉ trong vài giây.

-

Nguồn cung cấp phương tiện linh hoạt

Nguồn cung cấp phương tiện linh hoạt có thể di chuyển ba chiều đến bất kỳ vị trí nào và biến mất một cách kín đáo vào trần nhà chỉ bằng một nút bấm.

-

Máy dán cạnh

Hệ thống đai ốc vít dẫn hướng trục chính không bôi trơn và không có khe hở đảm bảo ứng dụng keo chính xác trong máy dán cạnh.

-

Bàn bi-a

Một hệ thống truyền động có thể di chuyển một chiếc bàn cố định và có thể điều chỉnh trong hồ bơi mà không gặp bất kỳ vấn đề gì - bất chấp môi trường nước hồ bơi liên tục.

-

Hệ thống nổi

Thay đổi độ sâu của nước chỉ bằng một nút bấm: Conmag Engineering GmbH xây dựng sàn di chuyển có thể điều chỉnh cho hệ thống bơi lội với hệ thống ngược dòng tích hợp.

Thiết bị thể thao và phục hồi chức năng

-

Thiết bị tập đi

Một thiết bị giúp những người mắc chứng rối loạn vận động não có thể tập đi.

-

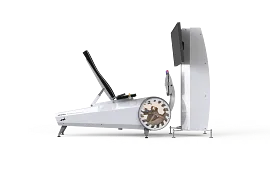

Thiết bị tập lướt sóng

Nhờ có thiết bị thể thao, thể lực được rèn luyện dựa trên các động tác lướt sóng - hoàn toàn không cần nước.

-

Thiết bị phục hồi chức năng cho trẻ em

Thiết bị phục hồi chức năng dành cho bệnh nhân bị rối loạn chức năng ở chi dưới.

-

Robot phục vụ thể thao và sức khỏe

Một robot phục vụ thể thao và sức khỏe giúp tăng cường thể lực, sức mạnh, sự cân bằng và tốc độ đi bộ theo cách vui tươi và tạo động lực.

Ngành đóng gói

-

Máy gấp và dán

Khi thiết kế máy dán gấp tùy chỉnh, nhà sản xuất máy chuyên dụng Bernhardt Maschinenbau dựa vào ổ trục trượt tuyến tính không cần bôi trơn và không cần bảo trì.

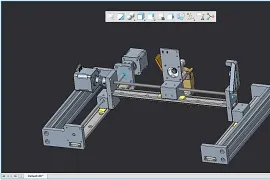

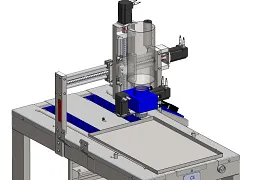

Công cụ máy

-

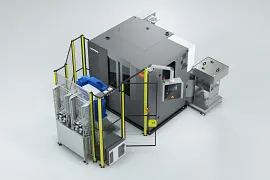

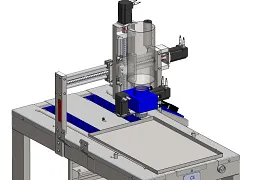

Máy CNC dòng M

Với máy phay CNC, những người đam mê và người dùng công nghiệp, ví dụ như trong xây dựng nguyên mẫu, có thể khám phá ra những sự tự do mới và biến bản vẽ CAD của họ thành hiện thực.