Thay đổi ngôn ngữ :

Đối với các chuyển động tuyến tính chính xác: Bộ truyền động Aris

-

Dữ liệu kỹ thuật:

- Những gì cần thiết: Chuyển động và định vị chính xác các bộ truyền động mà không cần bảo trì thường xuyên

- Yêu cầu: Độ chính xác cao nhất ngay cả trong điều kiện môi trường bất lợi, không cần bôi trơn và bảo dưỡng, không bám bụi bẩn

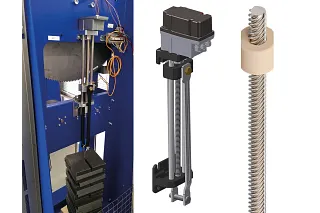

- Sản phẩm sử dụng: trục chính ren dryspin ® từ phạm vi tiêu chuẩn, đai ốc vít dẫn có hình dạng đặc biệt

- Thành công cho khách hàng: Một loạt sản phẩm mới cho hành trình chính xác, tiết kiệm chi phí do không cần bảo trì, có thể tính toán tuổi thọ với kết quả thử nghiệm nhanh và khách hàng quan tâm nhiều hơn do vật liệu đai ốc ren không quen thuộc

Truyền động tuyến tính có độ chính xác cao với cụm trục chính dryspin ®

Sản phẩm được sử dụng

Bạn có thắc mắc về công nghệ vít me drylin ® không?

Chuyên gia Thorben Hendricks của chúng tôi sẽ trả lời mọi thắc mắc của bạn về công nghệ vít me drylin ® Chỉ cần điền vào biểu mẫu liên hệ và chúng tôi sẽ giải đáp thắc mắc của bạn. Chúng tôi mong nhận được phản hồi từ bạn!

► Yêu cầu liên hệ trực tuyến

► Sắp xếp cuộc hẹn

► Hỗ trợ chuyên gia theo yêu cầu qua điện thoại hoặc qua chức năng trò chuyện video

► Đặt hàng mẫu miễn phí

Tư vấn & hỗ trợ

Hân hạnh được trả lời câu hỏi của quý khách

igus® Việt Nam+84 28 3636 4189Gửi e-mail

Báo giá và tư vấn trực tuyến

Thời gian làm việc:

Thứ Hai đến Thứ Sáu từ 8:30 đến 17:30

Online:

Thứ Hai đến Thứ Sáu từ 8:30 sáng đến 17:30