Thay đổi ngôn ngữ :

Các lỗi cáp thường gặp trong ứng dụng chuyển động

Đứt sợi dẫn điện (đứt lõi)

Đứt lõi (core rupture) là hiện tượng mất khả năng dẫn điện do các sợi đồng trong lõi bị đứt bởi lực cơ học hoặc ứng suất kéo trong quá trình uốn cong liên tục.

Nguyên nhân thường đến từ kết cấu bện không phù hợp, hoặc hướng và bước bện không đúng kỹ thuật. Mặc dù dây dẫn có tiết diện nhỏ sẽ linh hoạt hơn, nhưng dễ bị đứt sau thời gian dài sử dụng. igus® giải quyết vấn đề này bằng cách tối ưu hóa đường kính dây dẫn, hướng và bước bện thông qua các thử nghiệm độ bền nghiêm ngặt tại phòng lab.

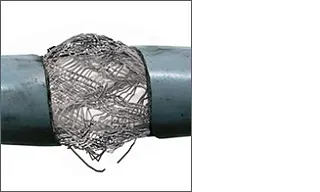

Xoắn cáp (Corkscrew)

Corkscrew là hiện tượng cáp bị biến dạng xoắn ốc rõ ràng ở bên ngoài, thường do quá tải cơ học hoặc ứng suất kéo khi uốn cong.

Lỗi cấu trúc cáp là nguyên nhân chính: lõi cáp được bện theo từng lớp, vỏ ngoài ép trực tiếp lên lớp lõi hoặc thiếu lõi trung tâm. Ngoài ra, sử dụng ngoài thông số kỹ thuật (bán kính uốn quá nhỏ, hành trình quá dài) cũng gây xoắn cáp.

Để ngăn chặn hiện tượng này, igus® sử dụng cấu trúc lõi xoắn thành bó (bundled cores) cho cáp có từ 12 lõi trở lên. Các lõi được bện nhiều lần quanh lõi trung tâm, giúp phân bổ lực kéo và nén đều, từ đó kéo dài đáng kể tuổi thọ của cáp.

Hư hại lớp cách điện

Hư hỏng lớp cách điện xảy ra khi lớp cách điện quanh dây dẫn bị rách hoặc mòn, dẫn đến chập điện. Nguyên nhân có thể do mỏi vật liệu dưới tác động uốn liên tục hoặc ma sát giữa các sợi bện. Khi các sợi đơn bị đứt, chúng có thể đâm xuyên qua lớp cách điện.

Để tránh điều này, igus® sử dụng các vật liệu như TPE hoặc PVC không kết dính, đã được kiểm nghiệm qua hàng triệu chu kỳ thử nghiệm trong phòng lab.

Hư hại lớp vỏ ngoài

Hiện tượng phồng hoặc hư hỏng vỏ ngoài là khi lớp vỏ mềm ra, biến dạng hoặc nứt vỡ, lộ phần lõi bện hoặc lớp chống nhiễu. Nguyên nhân có thể do chọn sai vật liệu so với môi trường sử dụng (dầu hoặc hóa chất), hoặc nhiệt độ môi trường quá thấp so với giới hạn tối thiểu ghi trên bảng thông số kỹ thuật. Khi vỏ cáp bị phồng hoặc hư hỏng, cần thay thế ngay lập tức.

Để tránh hiện tượng này, cần chú ý đến dải nhiệt độ hoạt động và khả năng chống dầu của cáp. Trong môi trường không có dầu, cáp PVC không chống dầu là đủ nếu nhiệt độ môi trường duy trì trên 5°C. Trong môi trường có dầu, igus® khuyến nghị dùng cáp chainflex® có vỏ PUR hoặc TPE. Cáp có vỏ TPE còn chịu được cả dầu gốc hữu cơ. Tất cả cáp chainflex® đều được đánh giá khả năng chống dầu theo tiêu chuẩn DIN. Ngoài ra, các vật liệu vỏ ngoài còn chịu được nhiệt độ liên tục -25°C (PUR) hoặc -35°C (TPE) khi sử dụng trong xích nhựa dẫn cáp.

Đứt sợi chống nhiễu

Đứt dây chống nhiễu là hiện tượng các sợi dây bảo vệ chống nhiễu điện từ bị quá tải. Hậu quả có thể là giảm hiệu quả chống nhiễu hoặc gây đoản mạch nếu đầu dây bị đứt xuyên qua lớp màng hoặc vải không dệt, tiếp xúc với lõi. Nguyên nhân thường do góc bện không phù hợp. Nếu sau khi tuốt vỏ, lớp chống nhiễu có thể dễ dàng trượt khỏi vỏ thì chứng tỏ cáp không phù hợp với ứng dụng trong hệ thống cấp điện động.

Để ngăn ngừa đứt dây chống nhiễu, igus® đã thử nghiệm và xác định được góc bện tối ưu - góc bện càng phẳng càng tốt – để chịu được ứng suất trong hệ thống dẫn động. Lớp vỏ bên trong chắc chắn cũng giúp bảo vệ thêm, không cho lớp chống nhiễu dịch chuyển tự do.

Tư vấn & hỗ trợ

Hân hạnh được trả lời câu hỏi của quý khách

Báo giá và tư vấn trực tuyến

Thời gian làm việc:

Thứ Hai đến Thứ Sáu từ 8:30 đến 17:30

Online:

Thứ Hai đến Thứ Sáu từ 8:30 sáng đến 17:30